Geisinger’s on-demand food delivery challenge

Geisinger, like many U.S. hospitals, uses the Hospital Consumer Assessment of Healthcare Providers and Systems (HCAHPS), to monitor patient satisfaction.

This national, standardized survey provides a valuable opportunity to learn where patient care and satisfaction could be improved.

From HCAHPS scores, Geisinger identified an opportunity to enhance satisfaction by transitioning from scheduled meal services, to a flexible, on-demand room food delivery system.

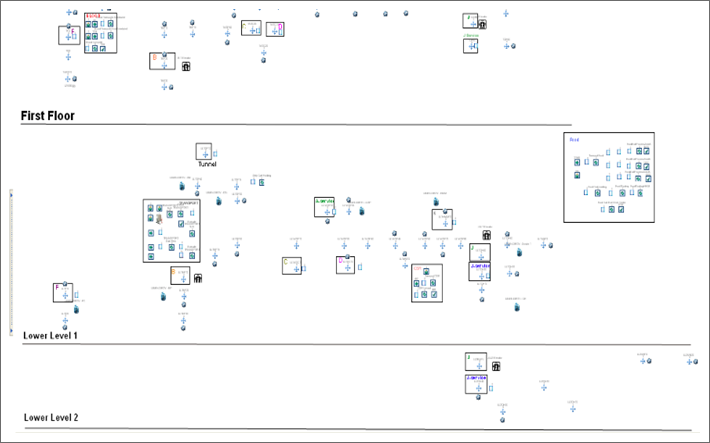

However, with a complex network of 18 inpatient units, each containing multiple services with overlapping pathways, there were several uncertainties around how best to implement the new system.

As such, Geisinger needed a comprehensive solution which would be able to model this important system in a risk-free environment and provide quick, reliable answers to their questions:

“How many staff will we need?”

“What will the optimal schedule be?”

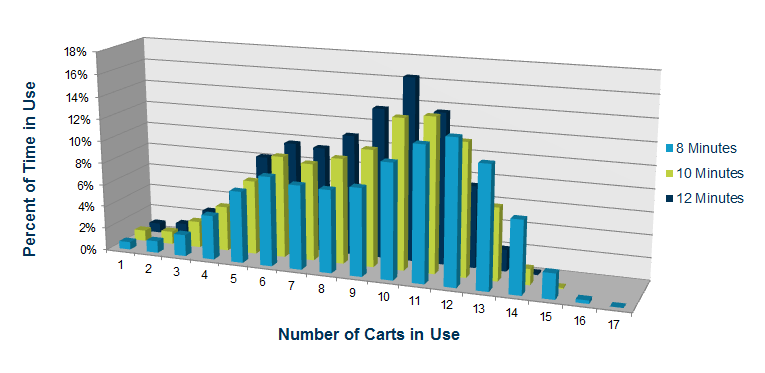

“Should we wait until delivery carts are full, or dispatch them at regular intervals?”

“How do we ensure a guaranteed service level – and what should that level be?”

Recognizing the complex trade-offs, and having previously achieved an impressive 40% reduction in workload for linen services, SIMUL8’s powerful simulation software was the clear, cost-effective choice for Geisinger.

Seth Hostetler, Lead Process Engineer, and his team applied a two-phase process to provide Geisinger’s management team with the vital information and recommendations needed to modernize the inpatient food system.

Find out how Geisinger approached the challenge using SIMUL8